Prototype electrochemical silicate sensor progress

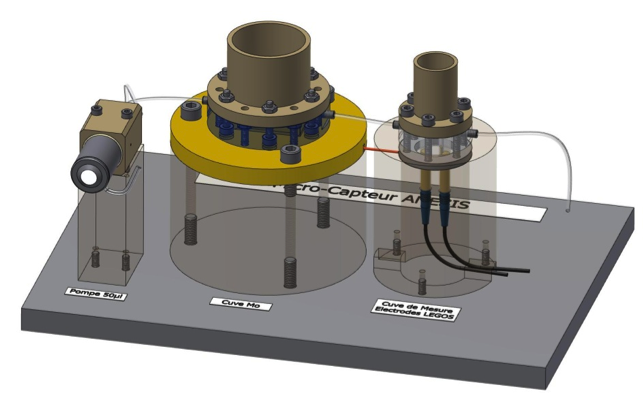

A 1st prototype of the silicate sensor developed by LEGOS-CNRS has been studied to determine its performance with respect to silicate detection. As shown in Figure 1, the prototype has 2 cells, the first one for the oxidation of the molybdenum and formation of the silicomolybdic complex (see earlier article). The complex is then transferred to the 2nd cell to be detected. The flow of seawater injection is crucial, particularly for the transfer of the silicomolybdic complex into the 2nd compartment. It has to be very slow (3 µL/s) in order to avoid the dilution of the sample and should tend to a laminar flow.

Results obtained with this silicate prototype showed good results and allowed to detection of silicate in the concentration range of 1 to 140 µmol/L. A minimum diameter of 2mm for the gold working electrode is necessary to obtain a limit of quantification (LOQ) of 0.5 µmol/L.

Figure 1: Prototype of silicate detection with a micro-pump, the oxidation cell and the detection cell

With the experience gained with this laboratory prototype, the design of the silicate submersible sensor has been developed by another SenseOCEAN partner, NKE-Instrumentation together with LEGOS-CNRS. This cylindrical sensor of 100mm diameter and 186mm height without the connector (230mm with connector) includes a solenoid pump (Lee-Co®) placed into a dielectric oil compartment, to fill and clean the circuit, and the electronics placed into a dry compartment. The “top” of the sensor, in equipressure, is the “technical part” with the 2 electrochemical cells (<250mm3) and the different electrodes. The weight expected in the air is close to 2.5kg and the Subconn connector (without Modbus) initially used, will be replaced later with a 6-pin impulse connector.